"... quick and reliable shedding of dangerous leading-edge ice caps and good heat utilization."

"Comparison of Several Methods of Cyclic De-Icing of a Gas-Heated Airfoil" 1

Abstract

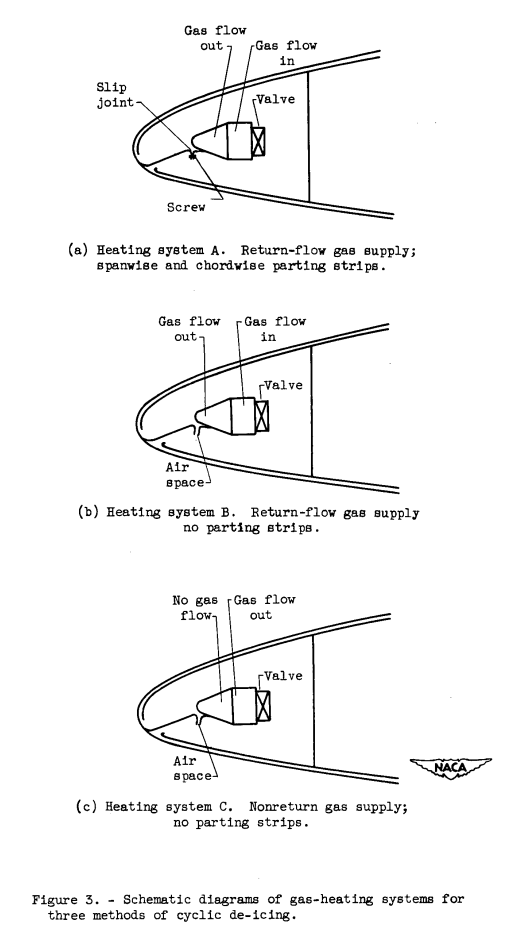

Several methods of cyclic de-icing of a gas-heated airfoil were investigated to determine ice-removal characteristics and heating requirements. The cyclic de-icing system with a spanwise ice-free parting strip in the stagnation region and a constant-temperature gas-supply duct gave the quickest and most reliable ice removal. Heating requirements for the several methods of cyclic de-icing are compared, and the savings over continuous ice prevention are shown. Data are presented to show the relation of surface temperature, rate of surface heating, and heating time to the removal of ice.

Discussion

read moreINTRODUCTION

The advent of high-speed, all-weather, jet-powered aircraft has emphasized the need for ice-protection systems that are light-weight, dependable, and automatic and that impose the least possible penalty on over-all aircraft performance. Anti-icing systems that evaporate …