"in icing conditions, periodic attempts should be made to throwoff the accretions by increasing propeller speed."

"The Effect of Ice Formations on Propeller Performance" 1

Abstract

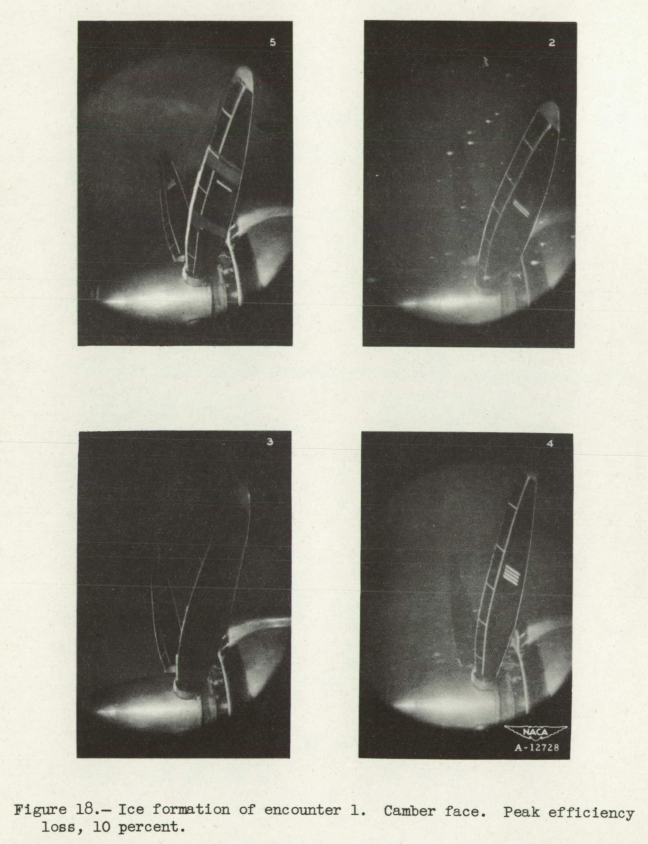

read moreMeasurements of propeller efficiency loss due to ice formation are supplemented by an analysis to establish the magnitude of efficiency losses to be anticipated during flight in icing conditions. The measurements were made during flight in natural icing conditions; whereas the analysis consisted of an investIgation of changes in blade-section aerodynamic characteristics caused by ice formation and the resulting propeller efficiency changes. Agreement in the order of magnitude of efficiency losses tobe expected is obtained between measured and analytical results. The results indicate that, in general, efficiency losses can be expected to be less than 10 percent; whereas maximum losses, which will be encountered only rarely, may be as high as 15 or 20 percent. Reported. losses larger than 15 or 20 percent, based …