"Most, if not all of the recent accidents on record having icing as the probable cause could have been prevented if the flight crews understood the serious nature of the situation and had applied appropriate corrective action." 2

Summary

Three publications on flight safety by Porter Perkins are reviewed.

Discussion

These publications are copyrighted. The first one, however, has a reuse license, and so much of the discussion will center on it.

"Tailplane icing and aircraft performance degradation" 1992 1

Ice on the tailplane (horizontal stabilizer) was identified as a risk on some aircraft:

Although the sensitivity of airplanes to inflight icing has been recognized for many years and can be minimized by ice protection systems, the advent of the medium-altitude turboprop commuter transport aircraft has resulted in renewed attention to the icing problem. This review of icing has been prompted by several recent accidents that apparently were caused by an oversensitivity to ice buildup on the horizontal stabilizer of these aircraft.

There was a coordinated effort to reduce risks due to tailplane icing:

Stall Can Be Caused by Ice On Tail Surfaces

A joint U.S. National Aeronautics and Space Administration (NASA)/FAA International Tailplane Icing Workshop to address this problem was held November 4-5, 1991, at the NASA Lewis Research Center in Cleveland, Ohio, U.S. Approximately 100 representatives from manufacturers, key special interest groups and airworthiness authorities of Canada, China, France, Germany, Italy, Japan, the Netherlands, Sweden, the United Kingdom, and the United States attended. The problem of horizontal tailplane stall caused by ice accretions also has been studied by the Swedish-Soviet Working Group in the Field of Flight Safety.

Ice accretion shape is a result of the rate of freezing on the surface. Low temperatures and droplet impingement rates (water concentration X velocity), along with small droplets, promote rapid freezing on the surface. Such conditions produce a rather smooth ice surface and pointed accretion shape called rime ice. However, temperatures near freezing, higher rates of accretion and larger droplet sizes result in delays in freezing when the droplets strike the surface. These conditions create irregular ice formations with flat or concave surfaces sometimes having protuberances (“double-horn” ice formation) facing the airstream either side of the airflow center or stagnation line. This type of ice formation is usually described as glaze ice.Ice shapes are of extreme importance because the contour, roughness and location of the ice formation on the various aircraft components can significantly deteriorate aerodynamic performance. Glaze ice shapes, runback ice (formed when water droplets flow in liquid form to freeze on a colder region of the airfoil) and ice caused by freezing rain (large droplets that do not follow the airflow but form ice on all surfaces they strike) can produce significant aerodynamic penalties by decreasing lift and stall angle and increasing drag and stall speed. This is caused by the ice destroying the aerodynamics necessary for peak airfoil performance.

Flight physics can make some phases of flight have a higher risk:

As the aircraft slows after flap extension, the requirement for downward lift by the horizontal tail increases to increase the angle of attack of the wing and produce a given amount of lift at a slower speed. With flaps full down and the aircraft at approach speeds, the angle of attack of the horizontal stabilizer is very high. It is high also because of the downwash over the tail created by the extended flaps. This will increase the angle of attack of the stabilizer even more.

This situation is where tailplane ice can cause trouble. A small amount of ice contamination on the leading edge of the horizontal stabilizer can interfere with the airflow on the underside of the stabilizer because it may be working near its maximum angle of attack.

Some incidents had common characteristics:

Generally, the tailplane stall problem that has been presented here seems to be associated with aircraft which have the following characteristics. They:

• Do not have powered control surfaces, and rely on aerodynamic balance to keep stick forces low;

• Have high efficiency flaps that produce relatively

• Have non-trimmable stabilizers;

• Have efficient stabilizers with short chord length and small leading edge radii; and,

• Mostly have inflatable boots for ice protection.One of the highlights of the NASA/FAA workshop was the recognition of the need for more education and training for pilots. This workshop recognized that much training, both initial and recurrent, has been provided for recognition and proper actions related to windshear; however, crew training for operations in icing conditions have been emphasized less. Some of the current recommended procedures suggested during crew training (e.g., increased airspeed) may actually exacerbate an already adverse situation at the horizontal tail.

"Aircraft icing problems-After 50 years.", 1993 2

Abstract

Although solutions to the aircraft icing phenomenon have been pursued for over 50 years, involving thousands of people, resulting in the availability of improved ice protection systems, fatal accidents caused by ice on critical aircraft components continue to plague aviation. We believe the rate of accidents caused by ice can be reduced if aviation safety is focussed on three key issues; pilot training, concurrent development of increased ice protection, and identification and codification of new regulations. With the possible exception of the hazards associated with tailplane ice, our knowledge of aircraft icing and the penalties associated with it has not changed substantially in the last forty to fifty years. Design criteria, hardware, and flight procedures have been in place for many years to enable safe flight In most icing environments. In addition, meteorological data is widely available so that well trained aircrews can make decisions to avoid areas where protection from icing Is questionable or not possible. Key issue is pilot training. Most, if not all of the recent accidents on record having icing as the probable cause could have been prevented if the flight crews understood the serious nature of the situation and had applied appropriate corrective action.

[Side note: I believe I was at the presentation of this paper in 1993.]

"Contending with Airframe Icing", 2002 3

ABSTRACT

Pilots need to be aware, under certain icing conditions, of the limitations of ice protection on their particular aircraft. FAA certification for flight into known icing does not ensure complete safety of flight in all icing encounters regardless of skills or aircraft capability. Too many accidents where icing was a contributing factor attest to these facts. Most of the time flight crews will not encounter an extremely severe condition. However, icing conditions are so widely variable that by chance they will encounter a condition in which they are unprepared. Many years of flight research in icing by the authors have provided the opportunity to experience and measure a wide range of icing conditions in which the performance losses and flying qualities of the aircraft were determined. These results are described in this paper.

Figure 1, "Various Ice Accretion Shapes Observed In Icing Research Flight Program", is quite interesting, but copyrighted, so it will not be reprinted here. It classifies ice shapes not in just the usually three types (rime, glaze, and mixed), but into ten types.

Some figures came from Perkin's earlier works, reviewed in Meteorology publications by Porter Perkins:

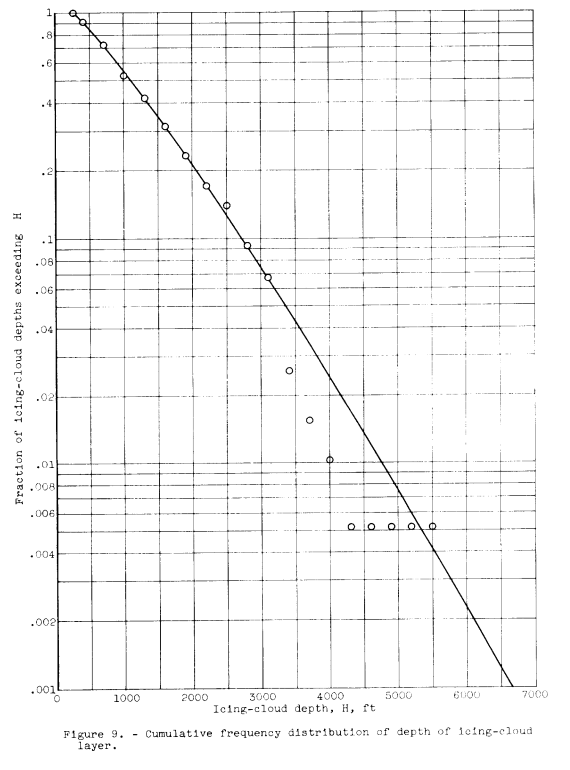

Figure 9 of NASA-MEMO-1-19-59, reused as Figure 6.

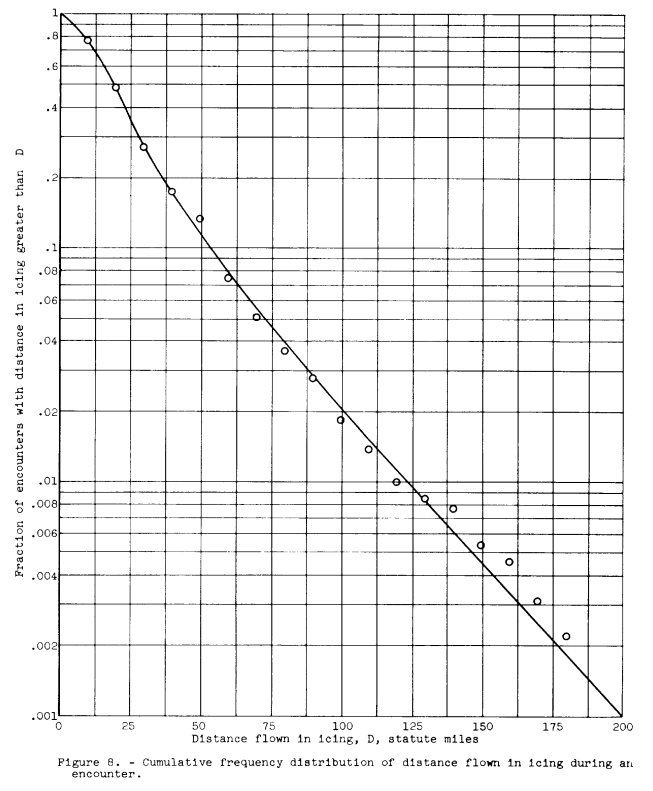

Figure 8 of NASA-MEMO-1-19-59, reused as Figure 7.

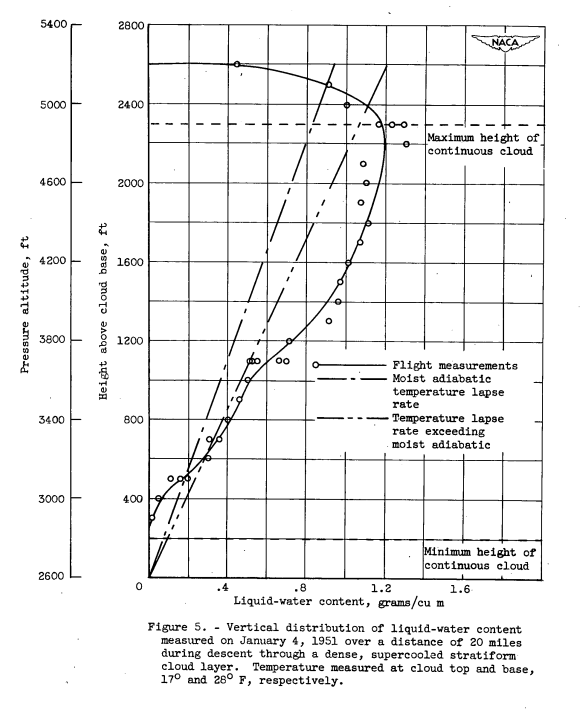

Figure 5 from NACA-RM-51D18, reused as Figure 8.

Conclusions

The flight crew training recommendations noted above in part resulted in a NASA Aircraft Icing Training series. These are focussed on pilots' needs, but are accessible to anyone interested in aircraft icing.

Flight safety is an ongoing effort. For example, while large drop icing conditions such as freezing rain were noted in many of Perkins works, including "Tailplane icing and aircraft performance degradation" above, the air transport system as a whole (regulators, airline, manufacturers, pilots, etc.) did not entirely realize the importance of those conditions until an accident in 1994 4. The official accident reports are not easy to read 5 6, but are highly recommended. That accident set a number of efforts into effect, including new regulations 7.

Citations

References were cited at scholar.google.com these many times:

Tailplane icing and aircraft performance degradation: 1

Aircraft icing problems-After 50 years: 12

Contending with Airframe Icing: 0

Related

This is part of the Porter Perkins series.

Notes

-

Perkins, Porter J., and William J. Rieke. "Tailplane icing and aircraft performance degradation." Accident Prevention, Copyright © 1991 FLIGHT SAFETY FOUNDATION INC. ISSN 1057-5561. flightsafety.org "Articles in this publication may be reprinted in whole or in part, but credit must be given to: “Flight Safety Foundation and Accident Prevention,” as well as the author." ↩

-

Perkins, Porter, and William Rieke. "Aircraft icing problems-After 50 years." 31st Aerospace Sciences Meeting, AIAA-93-0392. 1993. arc.aiaa.org ↩↩

-

Perkins, P. and Ranaudo, R., "Contending with Airframe Icing," SAE Technical Paper 2002-01-1518, 2002 sae.org jstor.org [can be viewed at no cost with registration] ↩

-

American Eagle Flight 4184, October 31, 1994. wikipedia.org ↩

-

25.1420 Appendix O Supercooled large drop icing conditions. ↩